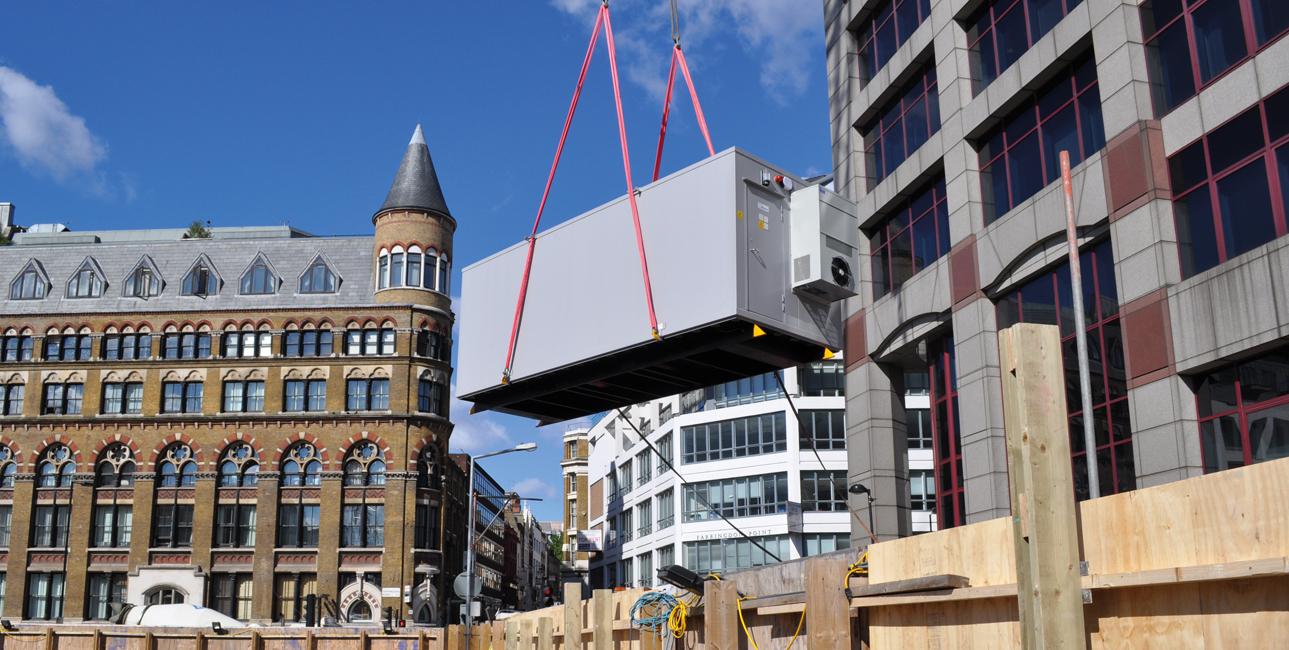

Relocatable Equipment Buildings.

Eldapoint's Relocatable Equipment Buildings (REBs) stand as a testament to our commitment to quality, innovation, and adaptability. Expertly designed to accommodate safety-critical railway signalling and telecommunications equipment, our REBs are strategically positioned trackside. They ensure the utmost strength, security, and adaptability, making them resilient against extreme weather conditions and perfectly suited for the demanding railway environment.

The Eldapoint Advantage

With over 55 years of experience, Eldapoint has been at the forefront of delivering sustainable and cost-effective REBs. Our legacy in the industry is built on trust, reliability, and a deep understanding of our clients' needs. Our commitment to excellence ensures that our relocatable equipment buildings are not only robust but also highly flexible. They can be fully tailored to meet a diverse range of requirements, making them suitable for various sectors beyond just railways.

Key Features of Our REBs

-

Modular Design: Our REBs are modular, allowing for easy transportation and installation. Once constructed, they are rarely relocated, ensuring stability and longevity.

-

Advanced Technology Housing: Designed to accommodate railway signalling, telecoms, and power systems, our REBs play a pivotal role in the efficient operation of rail applications. They house essential equipment such as signalling & interlocking systems, electrification & plant power systems, switchgear, and uninterruptible power supplies.

-

Safety and Security: Eldapoint's REBs are constructed with a focus on safety, ensuring the protection of critical railway equipment. They are also designed to offer high security, safeguarding against potential threats.

-

Tailored Solutions: From cooling systems and fire suppression systems to rack infrastructure and environmental monitoring, our REBs can be customised to include a range of equipment fit-outs based on specific requirements.

-

Energy Efficiency: Our REBs are designed to maximise energy efficiency, leading to reduced operational costs.

Versatility and Applications

While our REBs are primarily used in the railway sector, their adaptability means they can be utilised across various industries. From telecommunications to energy and utilities, their strength, security, and flexibility make them an ideal choice for any sector requiring relocatable equipment housing. This versatility is a testament to our design philosophy, which places adaptability at its core.

Dive Deeper into REBs

For those keen on understanding the intricacies and benefits of REBs, we've got you covered. Explore our detailed blog post which delves into the world of Relocatable Equipment Buildings. Additionally, our manufactured REBs case study showcases our expertise in action, highlighting our commitment to the rail sector. And if you're curious about the broader applications of REBs, discover why they are the ideal solution for remote locations.

If you’d like to learn more about our REBs, get in touch today by calling 0151 548 9838 or by filling out our simple enquiry form and a member of our specialist team will be in touch.