Remote site operations have always faced the challenge of building and maintaining infrastructure in harsh and isolated environments. Traditional construction methods require significant time, effort, and resources, making it difficult to meet the demands of rapidly evolving industries. However, with the introduction of relocatable equipment buildings, the game has changed. Keep reading to find out why these buildings are the ideal solution for remote locations and why you should choose Eldapoint for your project needs.

What is the difference between a relocatable building and a regular modular building?

Relocatable equipment buildings (REBS) and modular buildings are very similar in that they are both prefabricated structures designed to be easily moved and relocated. However, there are some key differences between the two.

Relocatable equipment buildings are typically designed for specific uses such as housing or equipment storage and are often used in industries such as rail, construction, mining or oil and gas. They are built to be transportable and can be moved from site to site as needed.

Modular buildings, on the other hand, are often designed to be more permanent structures. Whilst they are also prefabricated off-site and assembled on-site, they tend to be used for commercial or residential purposes such as offices, additional classrooms or pop-up shops.

Why are relocatable buildings ideal for use in remote locations?

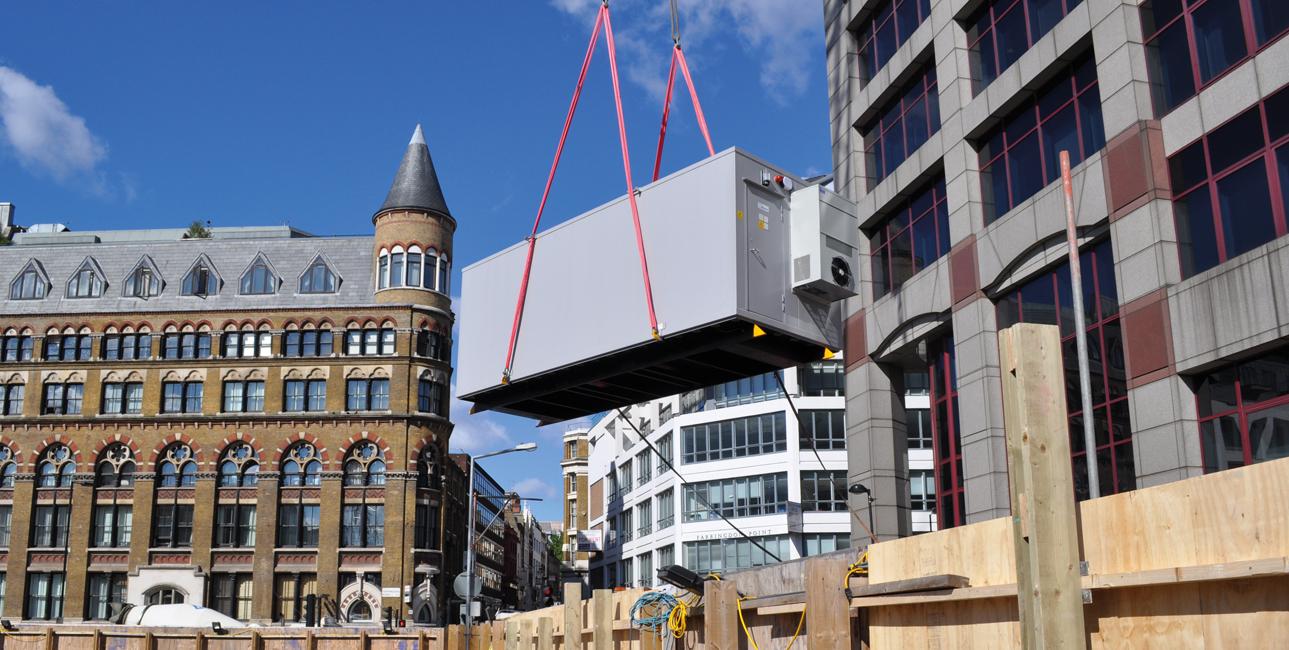

Relocatable equipment buildings are designed to be easily moved and relocated as needed. These buildings are constructed off-site in a factory setting and then transported to their final destination, where they can be quickly installed and put into use, enabling companies to set up operations in even the most remote and challenging locations. They are often used in situations where temporary or semi-permanent buildings are needed, such as construction sites and railway lines.

One of the main advantages of relocatable equipment buildings is their flexibility. Because they can be easily moved and reconfigured, they can be adapted to a variety of different uses and locations. They also tend to be more cost-effective than traditional construction methods, since they can be produced quickly and with less waste.

When using REBs in remote locations, it’s important to consider factors such as climate and terrain, your building may need to be modified to withstand extreme temperatures or high winds, and they may need to be elevated or anchored to prevent damage from floods or earthquakes.

Why choose Eldapoint for your relocatable equipment buildings?

We manufacture each REB at our facilities in Knowsley, using approved high quality materials. Our ability to design and manufacture bespoke REBs has enabled us to establish ourselves as a market leader within the sector and create structures used nationwide for various projects.

We have more than 55 years of experience in supporting our clients, delivering sustainable, highly flexible buildings that can be tailored to suit various requirements across different sectors. We are currently working to develop new building designs which offer increased value for money and shorter lead times

If you are interested in acquiring an REB for your next project, get in touch today by calling +44 (0)151 548 9838 or filling out our simple enquiry form and a member of our experienced team will be in touch.